-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

- burster

- Sensors

- Torque sensors

- Non-rotating applications

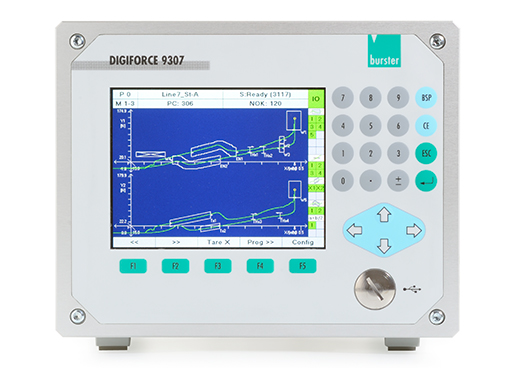

- DIGIFORCE® 9307

DIGIFORCE® 9307 Press-fit Control

Measuring accuracy of up to 0.05 %, sampling rate 10 kHz maximal, innovative evaluation elements, i.e. windows, thresholds, trapeziums, envelope curves, freely definable mathematical operations, two synchronous processes can be monitored, 128 measuring programms, intelligent Signal sampling, programmable I/O functions, Ethernet, USB, RS232, extensive diagnostics and statistical analysis, all usual sensor interfaces, variable fieldbus interfaces, powerful PC Software

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Comprehensive process monitoring delivered by innovative evaluation elements window, thresholds, trapeziums, envelopes and mathematical operations

- High measurement accuracy 0.05 % possible at 10 kHz sampling rate

- Flexible process integration thanks to a range of Fieldbus interfaces

- Simultaneous monitoring of two synchronous processes

- Ultra-fast evaluation and data transfer for dynamic measurements

- Ethernet, USB, RS232 as standard

- Up to 128 measurement programs for a large variety of parts

- Transfer of process, component and worker data

- Intelligent signal sampling using a combination of Δt, ΔX, ΔY

- Automatic sensor recognition due to burster TEDS

- DigiControl PC software with powerful data-logging function for process data

-

Product data

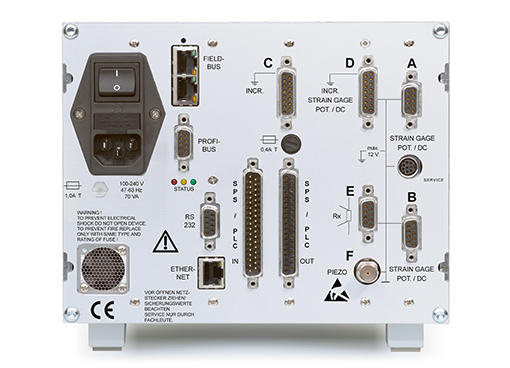

Model DIGIFORCE® 9307 Measurement channels 6 Max. amount of active measurement channels 3 Type of sensor - Strain gauge

- Potentiometer

- Process signal analog

- Incremental

- SSI

- EnDat

- Torque

- Angle of rotation

- Piezo

Measurement accuracy 0.05 % F.S. Fieldbus interfaces - PLC interface

- PROFIBUS

- PROFINET

- EtherNet/IP

- EtherCAT

Interfaces - USB

- RS232

- Ethernet

Max. amount of measurement programs 128 Evaluation time 15 ms Automatic sensor identification Option (EnDat/SSI) Autoconfiguration No Display - Numerical

- Graphical

Acoustic and optic error indication Yes Data logging Yes Components counter Yes Specific characteristics - Comprehensive process monitoring delivered by innovative evaluation elements

- Flexible process integration thanks to a range of fieldbus interfaces

- Simultaneous monitoring of two synchronous processes

- Ultra-fast evaluation and data transfer for dynamic measurements

- Transfer of process, component and worker data

- Intelligent signal sampling using a combination of Δt, ΔX, ΔY

- Independent and variable start/stop logic

- Convenient configuration screens

- DigiControl PC software with powerful data-logging function for process data

-

Description

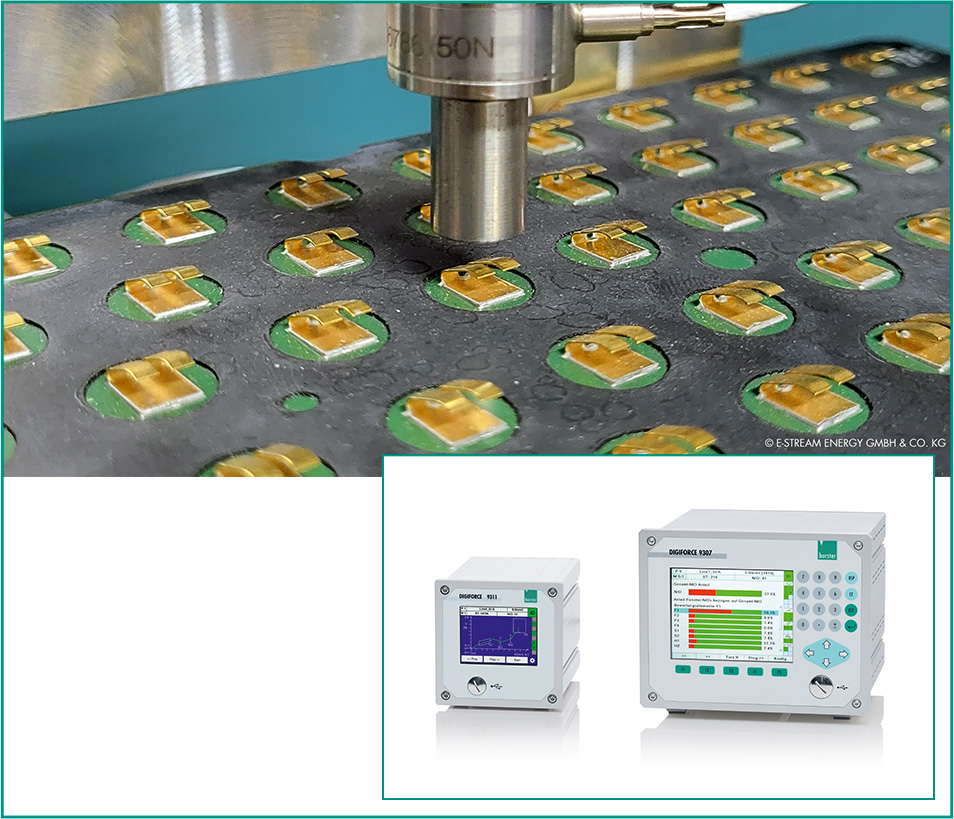

The DIGIFORCE® 9307 monitors processes in which precisely defined functional relationships between two or more measured quantities need to be demonstrated. These measured quantities are recorded synchronously during the manufacturing process or subsequent functional testing to produce a measurement curve, which is then assessed using graphical and mathematical evaluation techniques. After internal evaluation, the measurement curve and computed evaluation results are visualized on the color display and are also output at the external control interfaces. The processes in the controller are optimized by a powerful real-time operating system to achieve an extremely fast evaluation cycle: it typically takes just 15 ms to deliver the global OK or NOK evaluation result, which can then be analyzed by the higher-level controller.

In addition to the traditional evaluation windows with defined entry and exit sides, the DIGIFORCE® 9307 also offers thresholds, trapeziums of type X or Y and envelopes as graphical evaluation elements.Individual evaluation results from the graphical tools can then be combined by mathematical operations to provide even more analysis flexibility for a huge range of signal curves.

DIGIFORCE® has a wide range of process control applications, including monitoring processes such as joining, riveting or calking, or checking torque curves, for instance for hinges or high-quality rotary controls. Even complex signal/time curves (e.g. pressure curves, leaks etc.) can be monitored using the large choice of evaluation techniques.

Simultaneous recording of up to two Y variables (Y1 and Y2) with respect to a common X variable allows many applications to use one DIGIFORCE® controller to monitor two synchronous processes.

Alternatively, this feature can be used to evaluate an application with three process variables, for instance the force/displacement curve and associated current consumption of a lifting electromagnet. While DIGIFORCE® is used in many automated production areas, it is equally at home in the manual workstation, for instance to monitor force/displacement when using hand presses for assembly or for random spot-checking in goods inwards.

-

Data Sheet & Downloads

Data sheetBrochureOperation manualSoftwareFieldbusFurther info -

Accessories

-

Videos

Please accept marketing-cookies to watch this video.Please accept marketing-cookies to watch this video.Because every hit counts. DIGIFORCE® - Precision meets speed.

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9307 - Configuring the sensor channels and the measurement mode for recording an X/Y curve

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9307 - Configuring curve evaluation using the examples of a pass-through window, block window and threshold

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9307 - Configuring curve evaluation using the example of an envelope

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.