-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

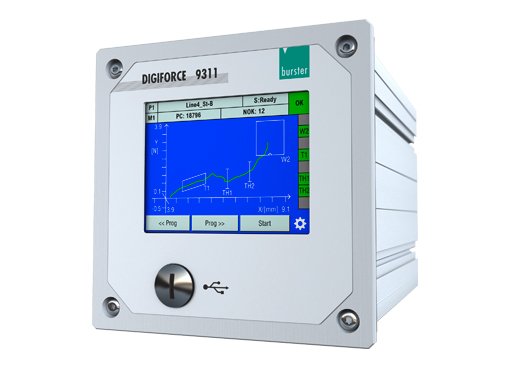

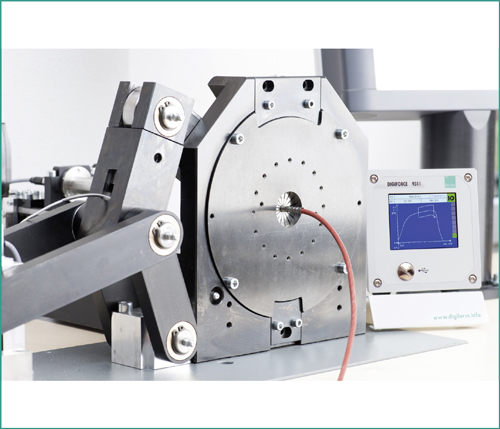

DIGIFORCE® 9311 Per monitorare operazioni di pressatura, rivettatura

Il DIGIFORCE® 9311 è il nuovo standard economico per il controllo della qualità dai tecnici specialisti in burster.

Il controllore di forza e spostamento pionieristico fornisce risultati di valutazione rapidi quando vengono richiesti elevati standard di qualità associati a elevati livelli di produzione.

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

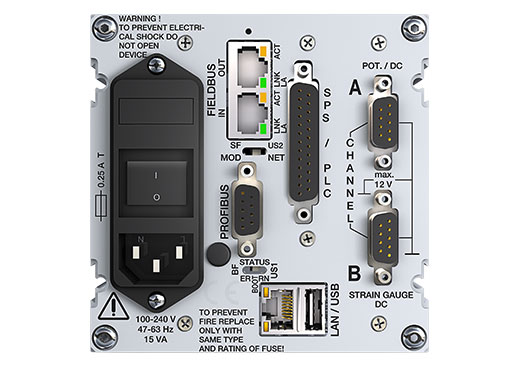

- Integrazione flessibile del bus di campo mediante PROFIBUS, PROFINET o EtherNet/IP

- Riconoscimento automatico del sensore mediante burster TEDS

- Display a colori touchscreen da 3.5"

- 16 programmi di misura

- Registrazione rapida dei dati su chiavetta USB

- Nuovi elementi di valutazioni (finestra trapezioidale e soglie)

- I/O configurabili dall'utente e 6 segnali di commutazione in tempo reale

- Configurazione automatica degli elementi di valutazione

- Gestione dei dati dell'operatore, amministratore e identificazione

- Possibilità di visualizzare e analizzare a display le ultime 50 misurazioni

- Registra e valuta una curva di andata e ritorno

- Valori in tempo reale grazie all'interfaccia Fieldbus interface

- Registrazione sincronizzata delle misure utilizzando il software per PC DigiControl nel caso di applicazioni multicanale

-

Product data

Model DIGIFORCE® 9311 Measurement channels 2 Max. amount of active measurement channels 2 Type of sensor - Strain gauge

- Potentiometer

- Process signal analog

- Piezo

Measurement accuracy < 0,2 % F.S.

< 1 % F.S. (Piezo)Fieldbus interfaces - PLC interface

- PROFIBUS

- PROFINET

- EtherNet/IP

Interfaces - USB slave (service interface on the front)

- Ethernet

- USB master

Max. amount of measurement programs 16 Evaluation time 25 ms Automatic sensor identification Yes Autoconfiguration Yes Acoustic and optic error indication Yes Data logging Yes Components counter Yes Specific characteristics - Flexible Fieldbus integration by PROFIBUS, PROFINET or EtherNet/IP

- Automatic sensor recognition from burster TEDS

- 3.5" colour touchscreen display

- 16 measurement programs

- Rapid data logging on USB flash drive

- New evaluation elements (trapezoid window and thresholds)

- User-configurable I/Os and 6 real-time switching signals

- Smart autosetup for evaluation elements

- Handles worker, admin and identification data

- Up to 50 most recent measurements available for display and analysis

- Records and evaluates a forward and return curve

- Live sensor values provided at the Fieldbus interface

- Synchronous logging of measurement data using DigiControl PC software for multichannel applications

-

Description

DIGIFORCE® 9311 is the new standard in efficient quality control. The pioneering force/displacement controller delivers rapid, precise evaluation results for applications that demand both high quality and high productivity. The smart performance features and intelligent hardware make test equipment quicker to set up, easier to use and capable of automatic integration in modern production systems. This unrivalled product specification gives businesses the added security and dependability they need for increasingly complex production processes.

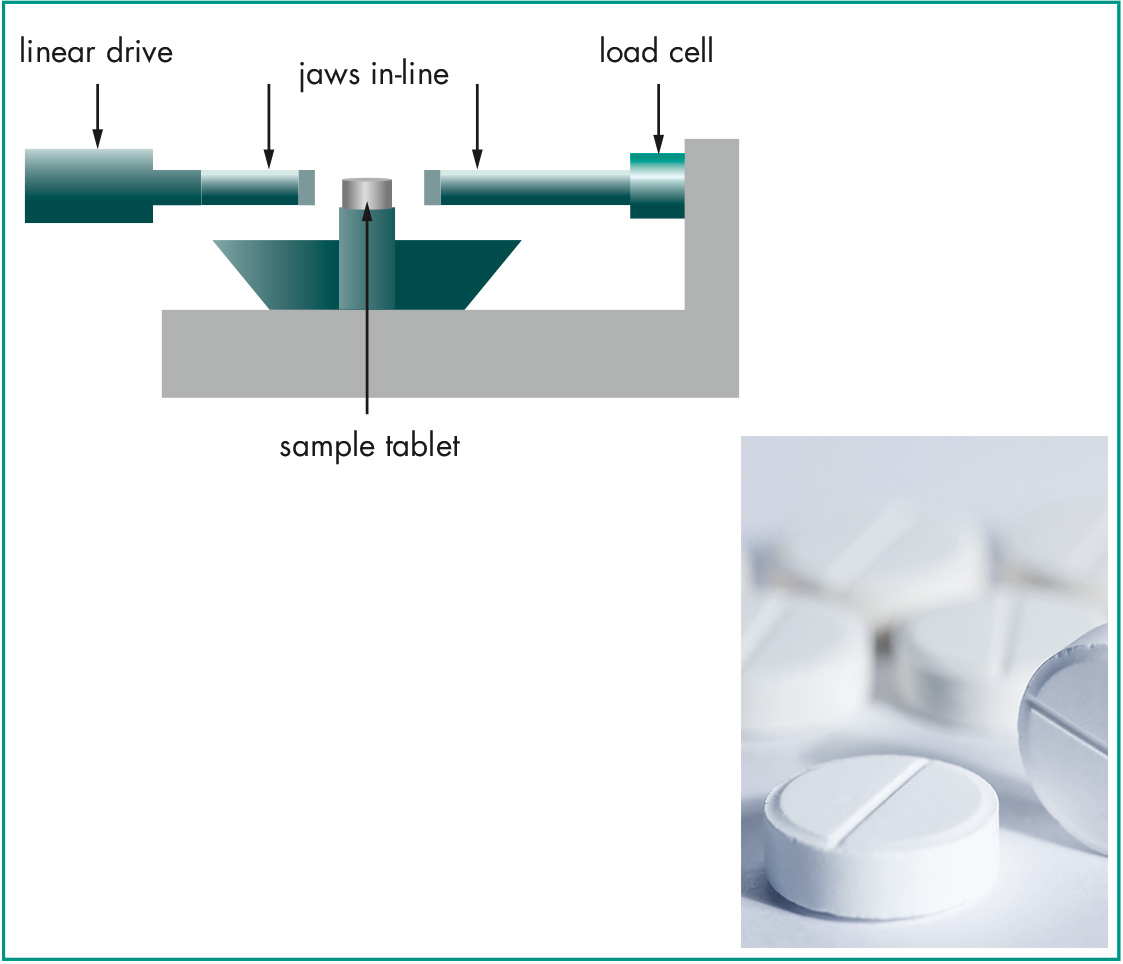

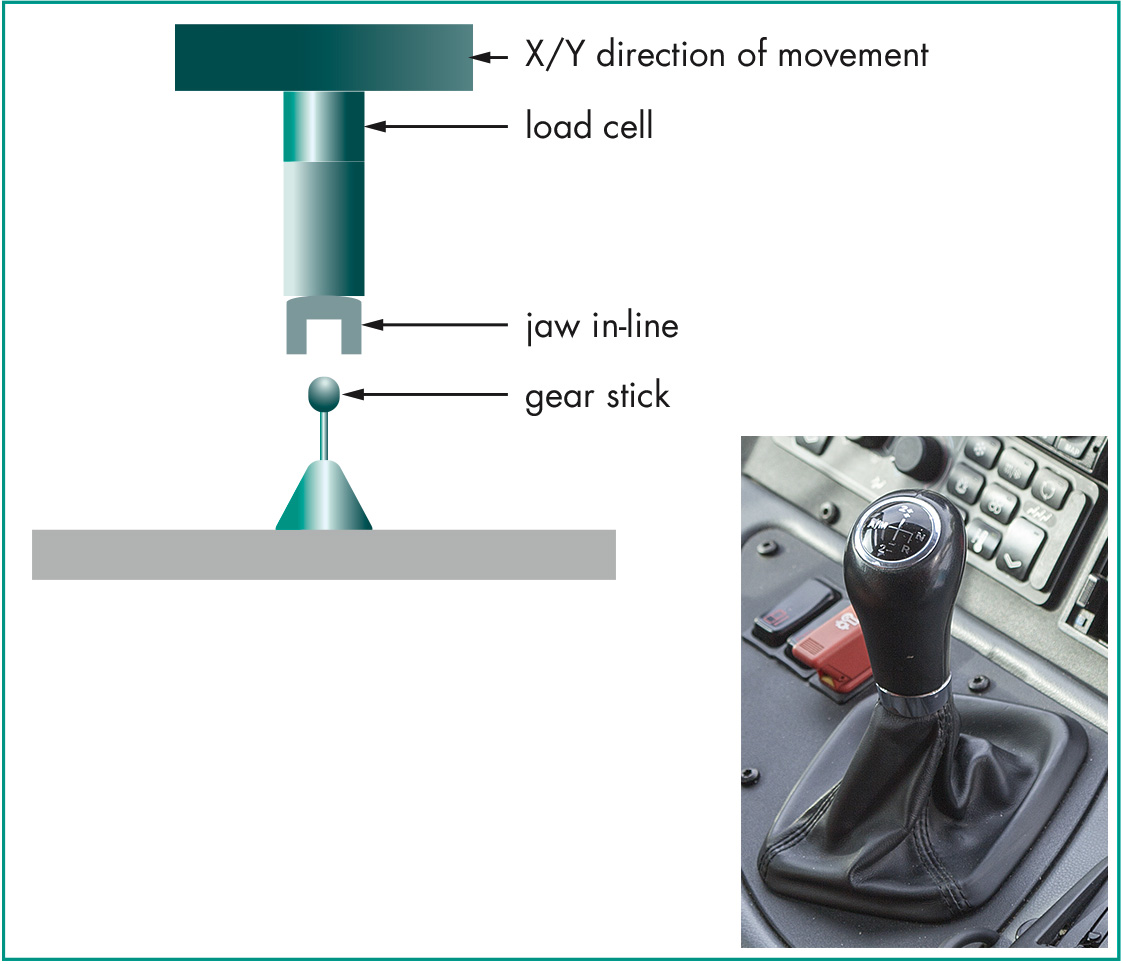

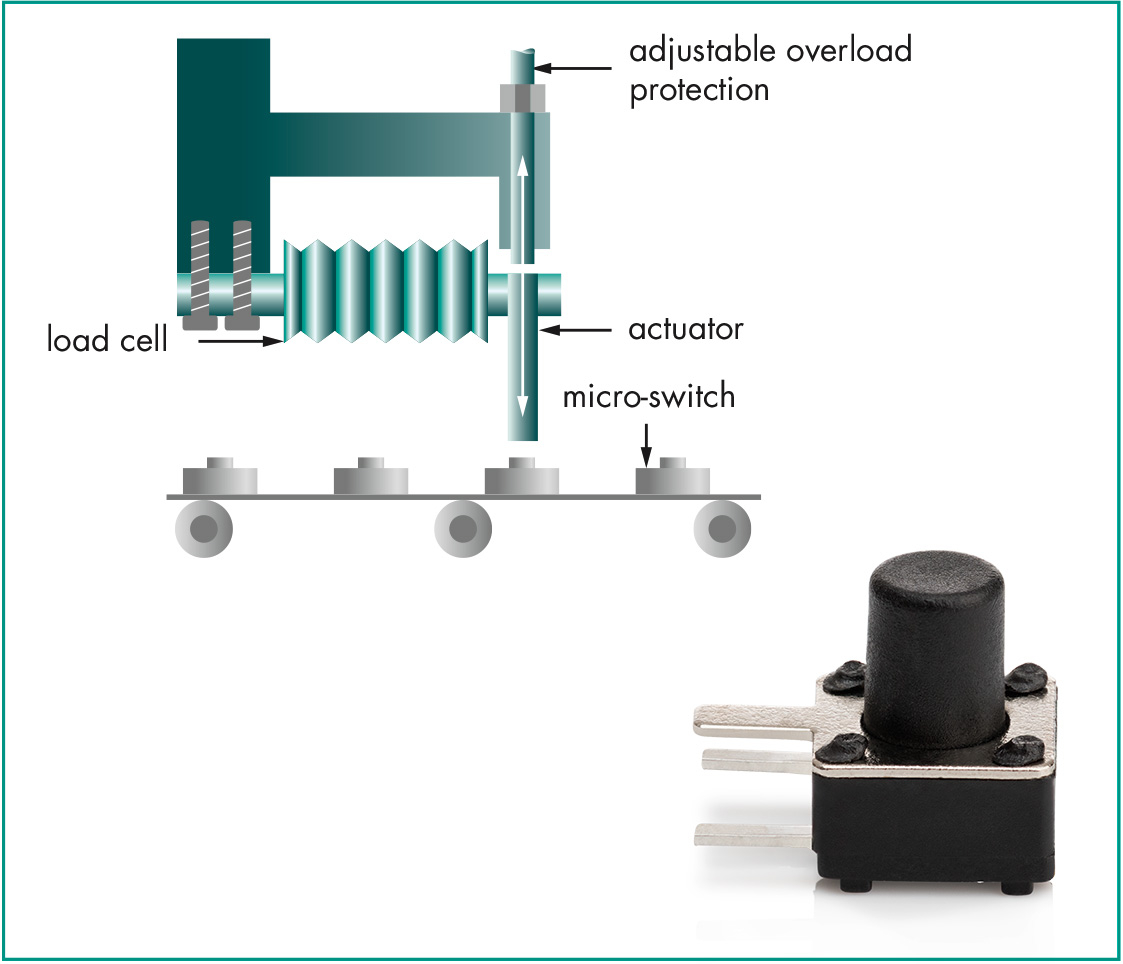

The DIGIFORCE® 9311 monitors processes in which precisely defined functional relationships need to be demonstrated between two measured quantities of the process. For instance when recording and monitoring processes such as press-insertion, joining, riveting, stamping or caulking, reliable quality control depends on synchronous and high-speed acquisition of measured values combined with analysis based on versatile evaluation elements. DIGIFORCE® 9311 provides the modern platform you need for this task, offering the widest choice of Fieldbus interfaces, including PROFINET, PROFIBUS and EtherNet/IP, to let you integrate the test setup in your particular control environment.

Even in fully manual workstations such as manual presses with force/displacement monitoring, DIGIFORCE® 9311 can be used for convenient and efficient process monitoring thanks to custom add-on functions like acknowledge and inhibit signals.

The DIGIFORCE® 9311 uses burster TEDS to provide automatic sensor recognition. This feature automatically reads an electronic datasheet stored in the sensor so that the relevant data can be used in the measurement-channel configuration. With no chance of operator error during setup or servicing, it’s best to play safe with burster TEDS. DIGIFORCE® 9311 offers versatile solutions for processes that need not just an OK/NOK evaluation but also data logging capabilities for recorded measurements and curves. Data from semi-automated and fully automated systems can be logged via the available Fieldbuses without slowing down production or via the Ethernet port (included as standard) linked to a server, host or local PC. The DigiControl PC software provides support with an automatic data logging mode that runs in parallel with production. There is also the option for high-speed data acquisition on a USB flash drive.

-

Data Sheet & Downloads

Data sheetBrochureOperation manualSoftwareFieldbusFurther info -

Videos

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9311 - Configuring the sensor channels and recording an X/Y curve

Please accept marketing-cookies to watch this video.Monitoring the crimping process of rotational symmetrical parts

Please accept marketing-cookies to watch this video.DIGIFORCE® 9311. The new benchmark for economic quality controls.

Please accept marketing-cookies to watch this video.Because every hit counts. DIGIFORCE® - Precision meets speed.

Please accept marketing-cookies to watch this video.Motek exhibition video burster

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9311 - Configuring curve evaluation using the examples of pass-through window, block window, trapezoid and threshold

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9311 - Configuring curve evaluation using the example of an envelope

Please accept marketing-cookies to watch this video.How to do: DIGIFORCE® 9311 - Configuring the sensor channels and the measurement mode using burster TEDS

-

Anwendungsbeispiele

Related products

Riferimenti

Nuova brochure: Press-fitting - the reliable way

Scoprite la nuova brochure Press-fitting - the reliable way. Controllo di qualità al 100% per le operazioni di pressatura manuale con molti esempi applicativi e informazioni focalizzate sul prodotto!

Brandnew: Torque Measurement Brochure

Scoprite la nostra nuova brochure Torque Sensor con molti esempi applicativi e informazioni focalizzate sul prodotto!

Italy

burster Italia S.r.l.

Via Repubblica, 10

24035 Curno

Italy

Fon: +39/035/618120

Fax: +39 035618250

infoburster.it

www.burster.it

SERVICES

- Qualified design, application support

- Process optimization

- Qualified integration support & training

- On-site trouble shooting

- Qualified phone & online support

- Local calibration service

burster Italia S.r.l.

Via Repubblica, 10

24035 Curno BG

Italia

Tel. +39/035/618120

infoburster.it

www.burster.it

Misure. La soluzione.

È con questa ambizione e da oltre mezzo secolo che burster, attore globale nel settore della tecnologia di misura di precisione, fornisce alcuni dei marchi più importanti al mondo con sensori, strumenti di misura di precisione e sistemi di misura per i segnali di processo. Tutto questo avviene attraverso la nostra sede di ricerca & sviluppo e produzione in Germania.

Dove la garanzia della qualità e il controllo della produzione giocano un ruolo significativo, burster è la risposta.