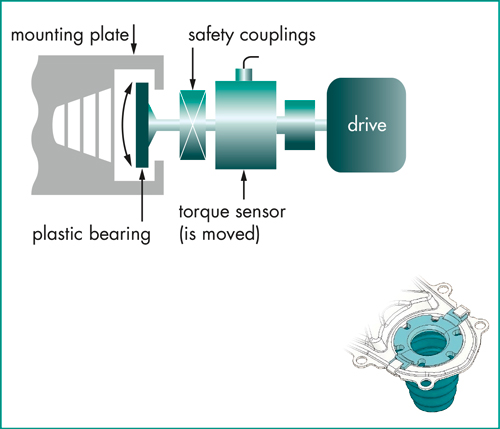

Measuring the static latching torque

for plastic bearings

- Linearity error 0.05 %

- Analog output signal 0 ... 10 VDC

- Built-in instrumentation amplifier cuts susceptibilty

- End-mounting facility simplifies mechanical construction

Task

Two precisely positioned plastic bearings are simultaneously fitted in a mounting plate by rotating through a fixed angle of 13 °. Das Reib- und Rastmoment soll gemessen werden.

Specific Requirement

Bedingt durch die notwendigen Einpresskräfte muss der Sensor für hohe axiale Kräfte ausgelegt sein.

Solution

The friction torque and latching torque lie in the range of 4.7 Nm to 9 Nm. The high-precision torque sensor model 8625 is used only to detect the jump in torque as the part engages but also to measure the friction torque needed while the part is running under the tab until it engages. The minimal linearity error allows tightly-toleranced monitoring of the distinct process stages. A safety coupling protects against overloading the torque sensor.

Sectors

Brandnew Brochure: Load cells

Discover our new brochure Load cells for production, automation, R&D and quality assurance with many application examples and product focused information!