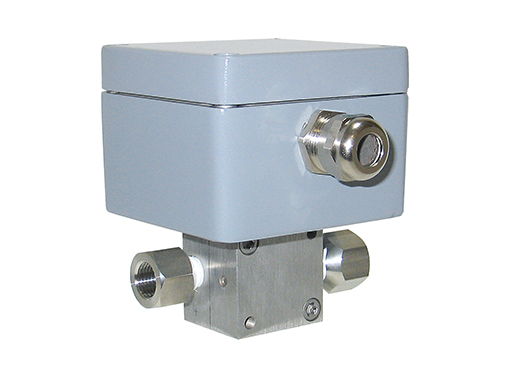

8303 Differential pressure transmitter

Robust, integrated measurement amplifier, stainless steel, for liquid or gaseous media, high line pressure

Brandnew Brochure: Load cells

Discover our new brochure Load cells for production, automation, R&D and quality assurance with many application examples and product focused information!