-

Australia

Australia

-

Austria

Austria

-

Belgium

Belgium

-

Bosnia and Herzegovina

Bosnia and Herzegovina

-

Brazil

Brazil

-

Bulgaria

Bulgaria

-

Canada

Canada

-

China

China

-

Croatia

Croatia

-

Czech Republic

Czech Republic

-

Denmark

Denmark

-

Ecuador

Ecuador

-

Finland

Finland

-

France

France

-

Germany

Germany

-

Great Britain

Great Britain

-

Greece

Greece

-

Hong Kong

Hong Kong

-

Hungary

Hungary

-

India

India

-

Indonesia

Indonesia

-

International

International

-

Iran

Iran

-

Israel

Israel

-

Italy

Italy

-

Japan

Japan

-

Liechtenstein

Liechtenstein

-

Luxembourg

Luxembourg

-

Malaysia

Malaysia

-

Malta

Malta

-

Mexico

Mexico

-

Montenegro

Montenegro

-

Netherlands

Netherlands

-

North Macedonia

North Macedonia

-

Norway

Norway

-

Philippines

Philippines

-

Poland

Poland

-

Portugal

Portugal

-

Republic of Singapore

Republic of Singapore

-

Romania

Romania

-

Serbia

Serbia

-

Slovakia

Slovakia

-

Slovenia

Slovenia

-

South Africa

South Africa

-

South Korea

South Korea

-

Spain

Spain

-

Sweden

Sweden

-

Switzerland

Switzerland

-

Taiwan

Taiwan

-

Thailand

Thailand

-

Turkey

Turkey

-

USA

USA

-

Vietnam

Vietnam

8431, 8432 Precision Miniature tension and compression load cell

Small dimensions, highly accurate, non-sensitive to disturbances, simple introduction of force, minimum lateral sensitivity, for tension and compression, model 8432 with overload stop

Too many products selected

Please notice that there is a limit of 5 products for the product comparison.

Your latest selection was canceled.

×-

Features

- Measuring ranges from 0 ... 2.5 N up to 0 ... 100 kN

- Protection class IP65

- Very robust against lateral forces due to supporting membranes

- Relative non-linearity from 0.15 % F.S.

- Model 8432 with overload protection for directions tension and compression

-

Product data

Model 8431, 8432 Measuring range 8431

0 … 5 N

0 … 10 N

0 … 20 N

0 … 50 N

0 … 100 N

0 … 200 N

0 … 500 N

0 … 1 kN

0 … 2 kN

0 … 5 kN

0 … 10 kN

0 … 20 kN

0 … 50 kN

0 … 100 kN8432

0 … 2.5 N

0 … 5 N

0 … 10 N

0 … 20 N

0 … 50 N

0 … 100 N

0 … 200 N

0 … 500 N

0 … 1 kN

0 … 2 kNDirection of force Tension and compression Standardization Option Signal output 8431

15 … 40 mV/V

0.4 mV/V

0,5 mV/V

2 mV/V

depending on measuring range8432

15 mV/V

0.75 mV/V

1.5 mV/V

2 mV/V

depending on measuring rangeProtection class IP65 Overload protection 8431

No8432

YesPull-plate No Load introduction button No Range of operating temperature -55 ... +120 °C Specific characteristics - Measuring ranges from 0 ... 2.5 N up to 0 ... 100 kN

- Protection class IP65

- Very robust against lateral forces due to supporting membranes

- Relative non-linearity from 0.15 % F.S.

- Model 8432 with overload protection for directions tension and compression

-

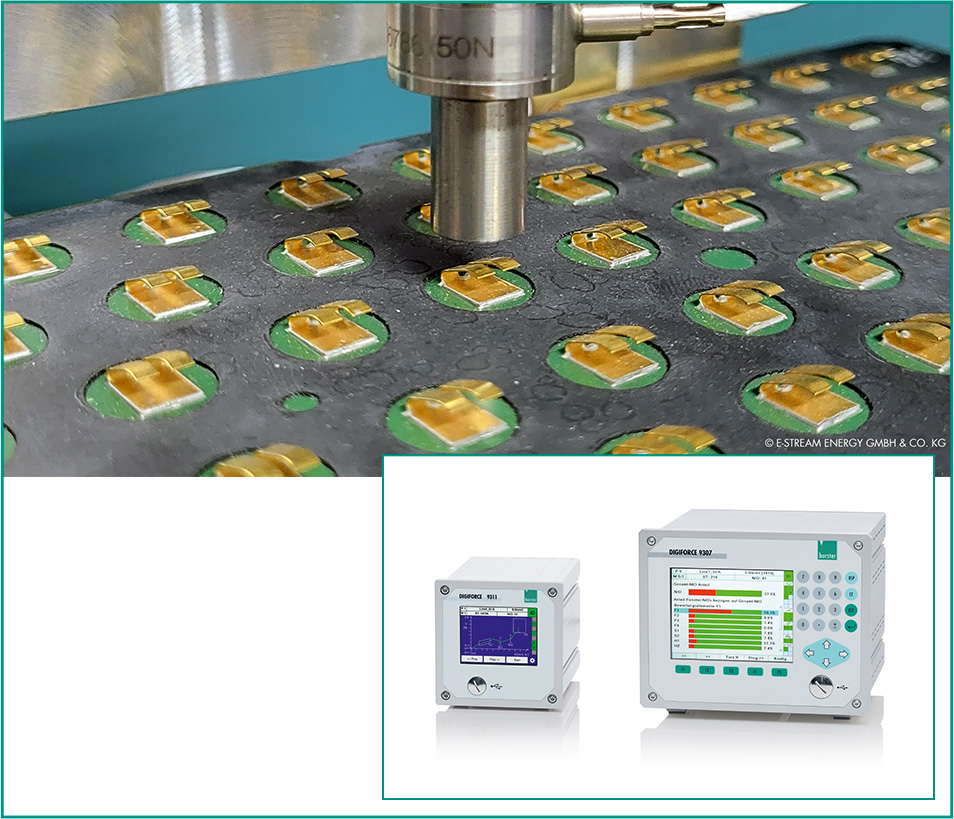

Description

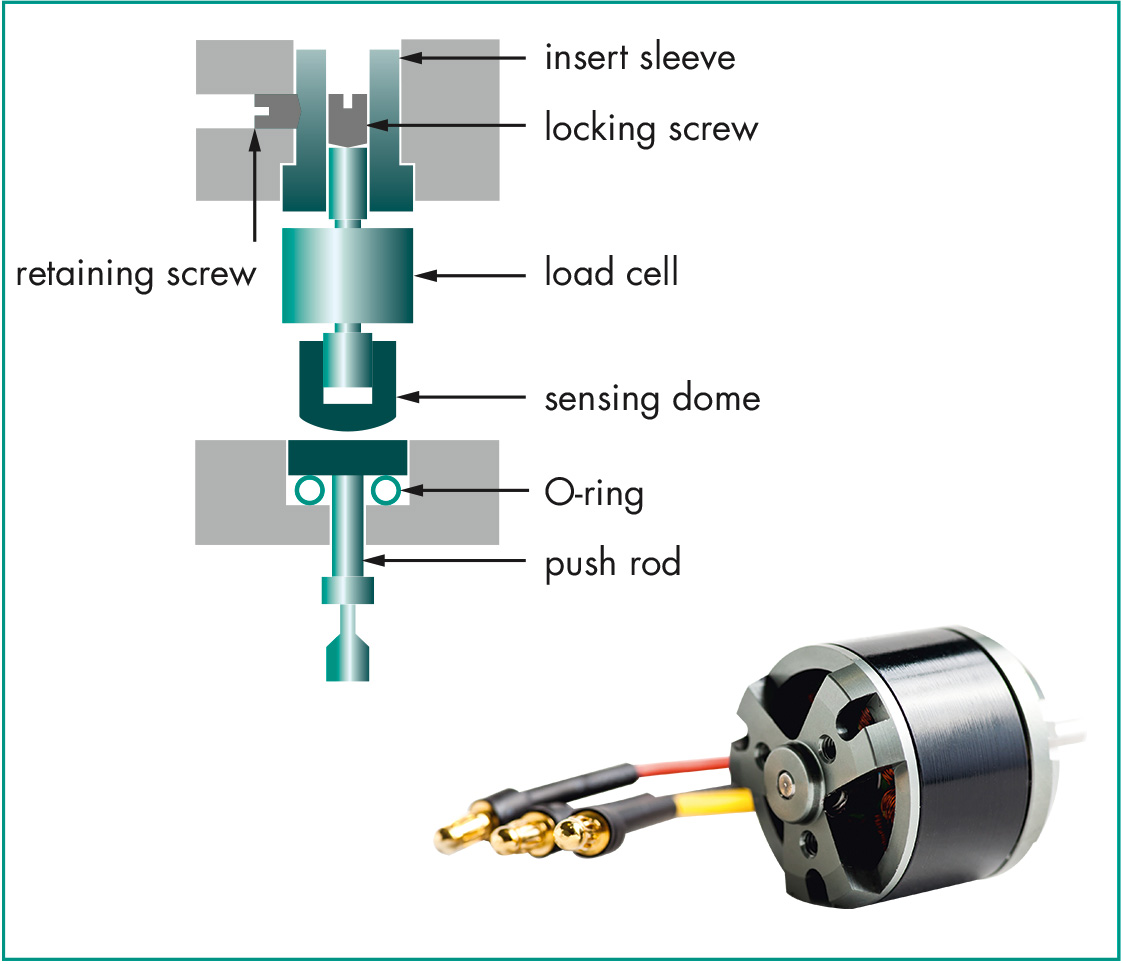

These models are among our most precise and yet mechanically robust miniature load cells. High accuracy, finely graded measuring ranges, small dimensions and the simple introduction of force via opposing threaded pins open up a wide scope of laboratory and production applications. Their sophisticated engineering with integrated support membranes and overload protection reduces additional design expense in many applications, e.g. for external overload protection or guiding the parts introducing force to the cell. The result is that less space is required, less material is used and less weight is involved. Last but not least, there is hardly any friction on components that could falsify the measurement result.

The force to be measured is introduced centrally and axially to the cylindrical sensor body in the tension or compression direction by means of the two threaded pins. This requires the sensor to be mounted without any elements touching the end faces of the sensor housing. Two stabilizing support membranes inside the sensors for the smaller measurement ranges minimize the effect of lateral forces and moments, while also ensuring long-term mechanical measuring stability. Even though the precision miniature load cell is designed to isolate the measuring element from external forces, torsion and bending moments on the sensor axis should be avoided. The sensors work position independent. They have an active side which acts directly on the measuring element, whereas the passive side is fixed to the housing.

-

Data Sheet & Downloads

-

Accessories

-

Videos

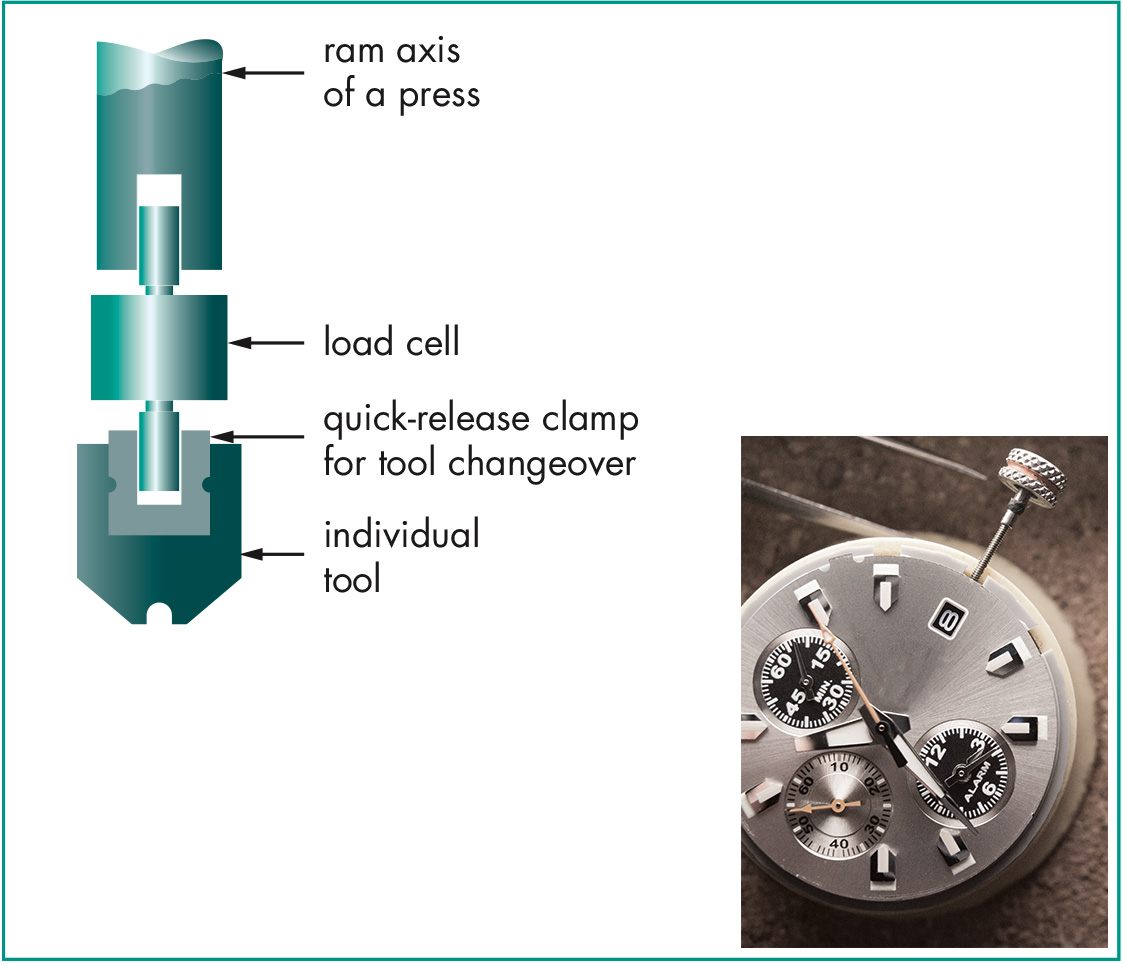

Please accept marketing-cookies to watch this video.Example showing load cell fitted under pre-load using quick-change device

-

Application Examples

Related products

Germany

burster praezisionsmesstechnik gmbh & co kg

Talstr. 1-5

76593 Gernsbach

Germany

Fon: +49 7224645-0

Fax: +49 7224645-88

infoburster.com

www.burster.com

Trade fairs

The Battery Show

18.06. -

20.06.24 -

Stuttgart,

70269,

Deutschland

burster gmbh & co kg

sensors & precision measurement

Talstr. 1-5

76593 Gernsbach

GERMANY

Contact:

Phone: (+49) 07224-6450

Fax: (+49) 07224-64588

E-Mail:

infoburster.de

The measurement solution.

It‘s with this ambition and for over half a century burster, a global player in the precision measurement technology industry, supplies some of the world’s most recognizable brands with sensors, precision measuring devices and measuring systems for sensor signaling processing. This is all done through our research, development and production headquarters in Germany.

Where quality assurance and production control play a significant role, burster is on board.